Hey everyone! Let's have a real chat about FPC (Flexible Printed Circuit) in the LCD industry. If you've ever worked on smartphones, car displays, tablets, wearables, or any kind of modern screen, you know these thin, bendy little ribbons are doing way more work than most people realize.

I've expanded this guide with more practical details, real-world examples, common pitfalls, and extra tips that engineers actually care about. It's still written like we're talking shop - no fancy AI tone, just straight talk. And of course, I've added plenty of photos so you can see exactly what we're discussing.

Why FPC Is the Real Backbone of Every Modern LCD Display

When someone shows off a beautiful high-res LCD or OLED screen, they talk about pixels, color accuracy, brightness, refresh rate... all that good stuff. But none of it works without a reliable FPC quietly handling the heavy lifting in the background.

This flexible circuit connects the main board to the glass panel. It carries super-fast data signals (like MIPI DSI, LVDS, eDP), power lines, touch signals, backlight control - everything. In foldable phones or flip-style devices, it bends tens or hundreds of thousands of times. In car dashboards, it deals with heat, vibration, and tight spaces. In medical or industrial equipment, it has to be ultra-reliable for years.

Screw up the LCD FPC design or bonding? You're looking at flickering screens, random lines, ghosting, touch insensitivity, or complete failure after a few months. That's why so many engineers lose sleep over FPC specs!

Here are some close-up looks at real FPC boards - check out those super-fine traces!

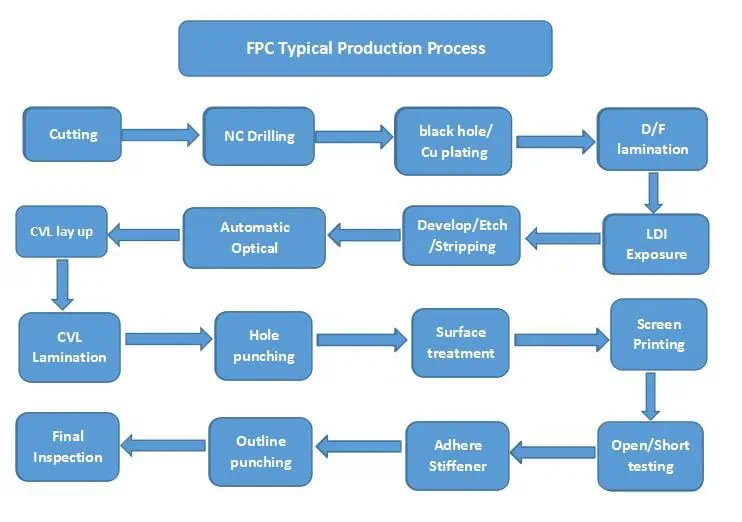

The Full FPC Manufacturing Process - Step by Step (What Actually Happens in the Factory)

Making FPC is quite different from rigid PCBs because everything has to stay flexible. Most factories follow this sequence (I've added some extra notes on what can go wrong):

1.Material prep - Start with FCCL (polyimide film + rolled copper foil). Thickness is usually 12–25μm for the film, copper 1/3 oz or thinner.

2.Drilling - Laser drilling for micro-vias (mechanical for bigger holes).

3.Plating - Copper plating to connect layers if it's double-sided or multi-layer.

4.Patterning - Dry film → UV exposure → development → etching. This is where trace width/spacing gets critical (down to 20/20μm or even finer for high-res displays).

5.Surface finish - ENIG (nickel + immersion gold) is the standard for LCD because it bonds perfectly with ACF.

6.Coverlay lamination - PI cover film glued on to protect traces.

7.Stiffener bonding - Add FR4 or extra PI at connector areas or high-stress zones.

8.Routing & shaping - Punch, laser cut, or V-cut to final shape.

9.Testing - Open/short, impedance, bending fatigue, peel strength, etc.

Common headaches? Moisture in the material before lamination = bubbles. Bad etching = open traces. Poor gold thickness = weak ACF bonding later.

These flowcharts make the whole process much easier to visualize:

How FPC Actually Gets Bonded to the LCD Panel (The Make-or-Break Step)

This is where most yield loss happens - attaching the finished FPC to the glass.

Typical sequence:

- Clean the glass panel pads super carefully.

- Apply ACF tape (anisotropic conductive film) precisely.

- COG - Press driver ICs onto the glass (huge precision needed).

- FOG - Align the FPC gold fingers to the glass pads, then heat-press (usually 180–210°C, 10–20 seconds, 2–4 MPa pressure).

- Cure, cool, then aggressive pull test + full functional lighting test.

Tiny dust, bad alignment (even 5–10μm off), insufficient pressure, or expired ACF = dead pixels, missing lines, or intermittent contact. Top factories aim for 99.5%+ first-pass yield here, but many struggle at 96–98%.

Here are real production-line photos of FOG bonding machines in action:

Real-World Optimization Tips - How to Make Your LCD FPC Better, Thinner & Cheaper

Here's where you actually gain a competitive edge. These are the tweaks experienced engineers swear by:

- Use rolled annealed copper (RA) instead of electrodeposited - much better fatigue life for dynamic bending.

- Design bend radius at least 3× total thickness (ideally 5× for millions of cycles).

- Route high-speed signals away from bend areas; add shielding layers (silver paste or copper pour) to kill EMI.

- Stiffeners only where needed - full-sheet stiffening adds weight and cost for no reason.

- Minimize gold area - only plate the actual contact fingers.

- Consider multi-layer FPC for complex routing (touch + display + backlight in one piece).

- Add onboard components (small caps, resistors) directly on the FPC to save mainboard space.

- Work with your supplier early - send them 3D models of the bending path so they can suggest layout improvements.

Wrapping It Up - Why FPC Mastery Makes All the Difference

In today's super-slim, high-performance LCD modules, a well-designed FPC is often the difference between a premium product and one full of returns. Whether you're doing automotive clusters, foldables, medical monitors, or industrial HMIs, getting the FPC process, bonding, and optimization right saves time, money, and a lot of headaches.

If you're currently fighting any LCD FPC issues - yield problems, bending failures, cost overruns, whatever - feel free to drop a comment. I'd love to hear about your project and swap ideas. Let's keep building better displays!

Discover the perfect display solution with MingHua Display - your trusted partner for custom LCD excellence!

At MingHua Display, we specialize in customized LCD modules tailored exactly to your project's needs. Whether you require high brightness LCD for outdoor sunlight-readable applications (up to 1500+ nits), wide temperature LCD that performs reliably from -30°C to +85°C, or rugged industrial screens built to withstand harsh environments like factories, vehicles, medical equipment, and marine settings - we've got you covered.

Our industrial LCD panels feature optical bonding, anti-glare/anti-reflection coatings, wide viewing angles, and long-term reliability, ensuring crystal-clear visibility even in direct sunlight or extreme conditions. From small sizes to large-format, standard or bar-type, capacitive touch integration to custom interfaces - we turn your ideas into production-ready displays with short lead times and competitive pricing.

Choose MingHua for high-brightness wide-temperature industrial LCD that doesn't compromise on performance or durability. Let's build the display that powers your success!